There is something about hiking for 6+ hours and eating cold oats and canned beans for 3 days straight that makes you long for civilization. But in all seriousness in order to end with a bang, we decided to climb the tallest mountain in the country, the Mulanje Massif or Mt. Mulanje. Rising 3002 meters above sea level, the peak named Sapitwa literally translates as “Don’t Go”. Not being an avid hiker or remotely outdoorsy, my experience reaching the peak was a struggle to say the least. In fact the only other mountain I have hiked in earnest is Michiru at the beginning of the trip. But with the suffering and pain I learned a valuable lesson in desirable difficulties and what it means to persevere.

In cognitive psychology, desirable difficulties is a method of effective learning that was pioneered by Robert A Bjork. The basic concept is that putting yourself through challenging situations helps you better learn concepts and improve long term performance. While climbing a sheer rock faces with no training and equating this to my life is a quite literal (and very inaccurate) interpretation of this, nevertheless it provided valuable insight into the field of engineering helping me learn more about myself and my limitations both physically and mentally.

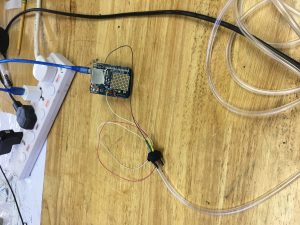

Much like hiking, the prototyping process needs to be done one step at a time. Whether brainstorming, choosing the best solution, or even prototyping, everything can be broken down into manageable sized chunks. I remember that when the project was first announced I selected protecting cup seals from dust in oxygen concentrators specifically because I did not know where to start with this project. One of my previous blog posts even detailed how hard it was to find the source of the problem when talking to technicians. But with guidance and by progressing slowly and purposefully, eventually my partner and I were able to build filter box prototypes and test them. More tests need to be done (some where inconclusive) and by no means is our solution the best or only solution, but at least it was a good start in my opinion. Now that my project, and by extension the internship is over, just like reflecting on the mountain it is amazing how much we’ve all accomplished in such a short time. Just like starting the internship by climbing a mountain and ending it by climbing a mountain everything has made full circle. Hopefully my project (either the improved internal or improved external air filter) will be continued after I go and can demonstrate a measurable impact. But for now what I am really looking forward to is a long shower, a hot meal, and a warm bed to sleep in.