Its been while without posting but work was still the order of the day. Soon after completion of hospital visits, more research on our project was done. We had to understand the properties of the material that we were to use for producing the compressor cup seal. The material is called the PTFE and its a self lubricating material. We thereafter had to come up with CAD drawing to use for laser cutting. At our disposal, we had three types of the PTFE material but we worked only with two. The difference mainly is the infill. Cup seals then had to be tested to compare the performance and the rate of wearing of the two materials.

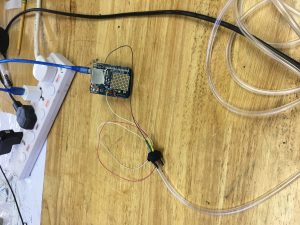

The testing of cup seals required us to collect pressure readings for a period of 3 days. why pressure? its because the function of cup seals is to prevent air leakages during compression in the compressor. low air pressure than the recommended range of 10 to 30 psi would mean something is wrong with the compression process; more likely air leakages in the cylinder. Collection of this data had to be done as often as every minute. pressure analyse was not an option hence we had to come up with an Arduion data logger. This was another interesting part of the project as we had to learn more coding and pressure sensors.

We tested one material so far (white one) and it turns out to wear out more rapidly than we imagined. Now looking forward to see the results of the green material which is under testing.