We have just finished our first week at the Polytechnic! Everything thus far has been incredible, though the best part has been meeting and getting to know the Malawian interns from the Polytechnic. As I mentioned before, the Polytechnic is where we will be working this summer; I’ve since found out it is the only engineering school in all of Malawi. Four students from the Poly were selected for the internship—Charles, Christina, Francis, and Andrew—and together with Catherine, Emily, and I, we compose the 7 person internship team working at the Polytechnic. Christina, Francis, and Andrew are all rising 5th year electrical engineers (engineering degrees at the Poly require 5 years), and Charles is a rising 5th year mechanical engineer. They are some of the most brilliant people I’ve ever met, and even in this short time I have learned a ton from them. Here are a few of those things:

- How to make improve devices.

- Feedback. We took out a few devices the Rice interns brought with us from Houston—a rolling frame used for physical therapy, flow splitter, respiratory rate timer, bCPAP heater—and we all brainstormed ideas for potential improvements that could be made. The Malawian interns immediately had dozens of new ideas for how to make these devices better. They suggested making the rolling frame more adjustable, to be appropriate for various ages of children; for the flow splitter, there were many ideas about how to substitute alternative designs in order to bypass the need for a check valve (which is hard to find and expensive); ideas were thrown around for how to automate a respiratory rate timer, incorporating it into a different existing BTB device that already measures neonatal breaths. For the bCPAP heater, which is the project I am most familiar with, Andrew had a great idea to incorporate an internal transformer and current limiting circuit within the control system box, which both makes it cheaper and uses less parts bought from the US. It was impressive to watch him draw up an entire circuit schematic without any outside resources in a matter of about ten minutes.

- Troubleshooting. Many of the Rice technologies that we brought had electrical circuits that were built by students with more of a medical background and less of an electrical background, plus the technologies had to survive three airplane flights over 35 hours. Somewhat expectedly, many of the technologies no longer were in perfect working order by the time they were unpacked at the Poly. The Malawian interns took lead in troubleshooting these devices, which was both an impressive and wild ride to be involved in: they worked very quickly, almost immediately identifying problems and rectifying them; when one part broke and no replacement was found, it was taken out and replaced with a completely different though equally functional component; when a power strip stopped working, they quickly took it apart, located a blown fuse, and replaced it. In less than two hours, all of our technologies were working, some even improved from initial design.

- Where to shop. We had many materials we needed to locate for a workshop happening this summer, as well as for rebuilding existing Rice technologies from local material. Charles, Francis, Andrew, and Christina helped us come up with about 12 stores around Blantyre we needed to go to, and we managed to get all of our shopping done in one day. Not only were we able to see more of the city and meet more people, but it was also an eye-opening experience in searching for parts to build our medical devices with. We went to five or six stores searching for simple, plastic y-splitters, which are really easy to find in the States and we had assumed would be no problem here, but couldn’t locate any. Charles called other mechanical engineers and we even asked our supervisor, Dr. Vueza, but no one had ever used or seen this part. The same story applies to our search for check valves. We went to hardware stores, plumbing stores, and medical supply stores, but we could only find a few new medical devices, not parts to build or fix those devices. The experience helped me to realize how important it is to build devices that can be created or maintained with local materials, otherwise they have much less of a chance to be built at the Poly or sustained in Malawi.

- Where to eat. The four Malawian interns came with us to the market and to Chipiku, a grocery store across from the Poly, to point out good food and good prices—they also took us to the cafeteria on campus, and restaurants Crazy Foods and Kips for lunches this week; the food so far has been great! They came over to our house Friday night, where Christina took charge in home making a huge meal of nsima, fish, and various veggies, while the US interns made a dessert of banana pancakes and cinnamon apples.

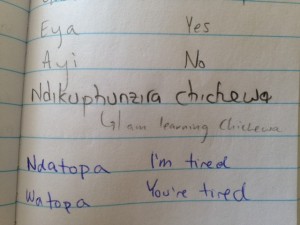

- How to speak. Every day, the Malawian interns help us with our Chichewa. We always carry small notebooks on us to jot down words and phrases, but it’s hard to keep up! So far we have some greetings, some goodbyes, and some common phrases (“no problem,” “it’s all good,” “thank you”) down, but one of our most commonly used phrases is, “ndikuphunzira Chichewa,” which means, “I am learning Chichewa.” This is what we use when we don’t understand anything (which unfortunately happens a lot.) When we speak Chichewa, most often we get a kind, hearty laugh in response—most likely due to our very slow speech and American accents—but occasionally we also get high fives for our efforts!

On top of everything that the Malawian interns have taught us, they are also some of the most kind, helpful, generous, and funny people I have ever met; the faculty at the Poly, as well as the other Malawians we’ve met where we are staying, in the shops, and in the market, have made us feel at home. I am very lucky for the chance to get to work with this team, and I can’t wait to see what projects we complete!