[10 July 2018]

After over a week of racking my brains to beat this laser cutter problem, we have our answer. By this time I’d practically memorized that maintenance manual, and had been communicating back and forth with a technician who was traveling through Thailand, by email. Email here meant walking back and forth between the Poly and Queens to mooch a connection off the CPAP office. Trying to have conversations like this made me think on how hard it must have been to get anything done before phones and telegraphs. Can you imagine waiting weeks for an answer by paper? Phone lines are amazing. I guess back before all that, you just had to resign yourself to waiting, or just figuring it out on your own.

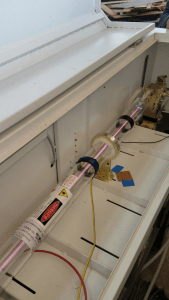

Anyway, after all these messages back and forth, the technician and I had come to a dismal conclusion. Either the laser tube was bad – which was highly unlikely, because it had been checked before being shipped from the factory – or the power supply had failed, despite indications that it functioning just fine. Both answers were uncertain, and both meant ordering another part and probably waiting an eternity for its arrival. There was a strong chance I’d be back in the USA before anything new would come, and without a working laser cutter, no Bilispec card parts. Without these parts, no way to train the Poly in making the cards, and without those cards, no point in training Queens how to verify their function with Bilirubin standards. It seemed all of my goals were now utterly blocked, so I’d already set to figuring out where else I could lend my help instead.

Once Andrew and Francis returned from out of town, I gave them the news. Francis sent one last email to the technicians, mentioning that we probably need to order a new power supply now.

Their reply: “but what about the power supply we sent you?”

Francis ran up to the package room at the Poly and asked whether there had been a second crate for us. Sure enough, it was there. It had been upstairs the whole time! We knew both a power supply and tube had been requested in the first place, but when we’d checked for packages, we’d asked for a package. We only received one, and accepted that. There’s a lesson about assumptions in there. Also, why on Earth the clerk didn’t mention a second crate at the time? I don’t know. But there it was.

Francis ran up to the package room at the Poly and asked whether there had been a second crate for us. Sure enough, it was there. It had been upstairs the whole time! We knew both a power supply and tube had been requested in the first place, but when we’d checked for packages, we’d asked for a package. We only received one, and accepted that. There’s a lesson about assumptions in there. Also, why on Earth the clerk didn’t mention a second crate at the time? I don’t know. But there it was.

Fast forward: we’re all ecstatic, the connectors have been re-soldered, the tube is in place. We power up the machine, directing the tube at a piece of crepe paper taped before the first mirror. The laser fired. Fire. The little paper burst into a flame! Blowing that out quickly and waving off the smoke, I thought to myself I’d probably need to pick out a different test material, but the important thing was the laser cutter was now working.

What a relief!

Rock climbing again tonight. Looking forward to blowing off some steam.