This past week the other Rice 360 interns and I have been diligently planning and preparing for our journey to Malawi. Majority of our time has been spent in the OEDK learning and building the the Rice 360 devices we will be implementing, assessing the material we will need to pack, and learning as many skills as possible before we depart. We are bringing an assortment of low resource medical devices to Malawi that Rice 360 student developed over the past semester and now it is our responsibility to take over their designs for valuable feedback.

Rice 360 Devices for Malawi:

- Clean Machine – removes medical tools in a timely manner after sanitation to prevent deterioration

- Phototherapy Mask – reusable eye mask to prevent retinal damage during blue light phototherapy of babies with neonatal jaundice

- OxyMon – continuous oxygen monitor that displays quantitative values of concentration and alerts clinicians of poor machine function

- Neonatal Temperature Monitor – easily monitor premature neonate’s temperature during kangaroo mother care

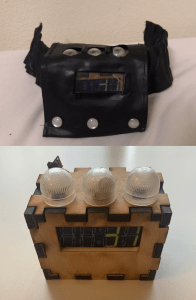

- IV Drip Lock – prevent non-clinicians from tampering with IV dosage

- Cervical Thermocoagulation Training Model – reusable training model that teaches clinicians how to perform thermocoagulation therapy on cervical cancer patients

- Ostomy Bags – reusable and sterile bags for patients with ostomy ports

- Ballard Score Training Model – training model that teaches clinicians how to accurately identify premature babies

During our time at the OEDK all the Malawi-bound interns including those going to be at the Malawi University Polytechnic and Queen Elizabeth Hospital, divided the projects among ourselves. Alex, another intern, and I teamed up to work on Clean Machine, Phototherapy Masks, and IV Drip Lock. As we read through each team’s information, we realized just how innovative each of these devices were. One of my favorites is the IV Drip Lock. It has such a simple design, yet is complex enough that non-clinicians are not able to open it without assistance or additional instructions which prevents patients from adjusting their dosage with the hopes of recovering quicker. It brings on a whole new perception about how simple designs can have an impact on someone’s health.

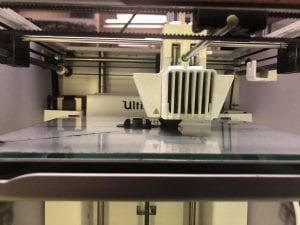

Together, Alex and I have sewn new phototherapy masks, 3D printed additional IV Drip Locks, and prepared the components to assemble clean machine once we reach Malawi. Learning how to recreate each of these devices required skills I had to learn on the fly including 3D printing, laser cutting, soldering, how to CAD and use Adobe Illustrator. Obviously I am by no means an expert in any of these areas, but I am proud of the progress I have made so far.

Another job we were tasked with in Malawi, is setting up a new innovation and design space in the Malawi University Science and Technology (MUST). So far, Rice 360 has already purchased the materials we will need to set up the studio, but it will be our responsibility to organize it and create a system to track the use of materials. During my time at the OEDK I have become accustomed to the culture of respecting the tools, materials, and people in the space as well as the willingness to teach one another and the engineering design process. Throughout our time at MUST I hope to impart this culture on the students and develop the space as a whole.

Once, these two weeks of preparation are over, I will be going home for two weeks before leaving for Malawi on June 3rd! I will spend this time mainly with family, making tons of lists, packing, and trying not to freak out that I will be leaving soon! On June 3rd, our journey will begin in Houston, then on to London, Johannesburg, Lilongwe and finally Blantyre, Malawi. I can’t say I’m too excited to sit still for over 31 hours of travel, but I’m sure it will pass by in the blink of an eye.

Looking forward to what awaits us in Malawi!

– S