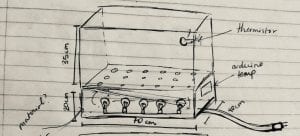

It is surreal that we only have a less than a week left in Malawi. Somehow the time has gone by and I didn’t notice it, but on the other hand we started prototyping! Our focus for the past couple of weeks (sorry it’s been a while since my last post) after the pitch competition has been on finalizing our solution design, get materials, and physically build our prototype. We started by making a few alterations to our final design transitioning from a water heat source to a light bulb heat source and deciding on the exact dimensions for each compartment. Once we had a plan in place, we transitioned towards dividing the work into three components the electronics, heating compartment, and the neonate’s compartment. For our first task, we collectively decided on how the heating system should operate:

final design transitioning from a water heat source to a light bulb heat source and deciding on the exact dimensions for each compartment. Once we had a plan in place, we transitioned towards dividing the work into three components the electronics, heating compartment, and the neonate’s compartment. For our first task, we collectively decided on how the heating system should operate:

- Contain a manual on/off switch

- Measure the temperature of the neonate’s heated environment

- Turn the light bulbs off when the temperature exceeds the desired temperature

- Turn the light bulbs on if the temperature falls below the desired temperature

- Alert nurses of the temperature

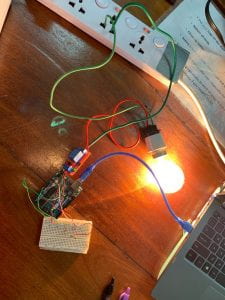

With these criteria in mind, we used various electronics, such as a thermistor, relay, Arduino, LEDs, resistors, and light bulbs, we spent multiple days trying to fit them all together. Each day we were able to build the circuit using the component and then program the Arduino to control the function of that component until we had a completed circuit. Of course, there were challenges along the way with not knowing the proper way to integrate the components together or the code not working, but eventually with enough trouble shooting we were able to acquire accurate temperature readings, automatically turn on/off the light bulbs, and indicate extreme temperatures. Not only were we able to work together and accomplish this task, but we took the time to teach each other the skills and reasoning behind each component so we understood their purpose (relays are really cool by the way).

Once we completed designing the electronics portion of our design, our next goal was to complete the heating compartment which contains the light bulbs, wiring, metal sheet, and insulating material. One challenge we faced in this portion of the design was obtaining the physical materials themselves. It seemed that the best way to know where to get the proper materials was by word of mouth. Luckily the design studio already had plenty of wood available to use, however, the more specific materials were difficult to find. Working with the materials we had in the design studio, we built a simple rectangular box out of sheets of wood. On the bottom face of the box, we decided to add a plank of wood across to attach the light bulbs parallel to bottom and ensure they fit within the specified dimensions of our design. We also added a metal sheet above the incand

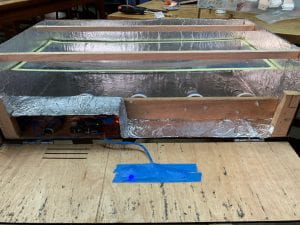

design was obtaining the physical materials themselves. It seemed that the best way to know where to get the proper materials was by word of mouth. Luckily the design studio already had plenty of wood available to use, however, the more specific materials were difficult to find. Working with the materials we had in the design studio, we built a simple rectangular box out of sheets of wood. On the bottom face of the box, we decided to add a plank of wood across to attach the light bulbs parallel to bottom and ensure they fit within the specified dimensions of our design. We also added a metal sheet above the incand escent light bulbs to retain heat and lined the inside of the box with aluminum to retain heat for a longer duration of time through insulation and radiation. As we continued to work, there were many decisions and adjustments that needed to be made such as adding a closed off housing area to separate the electrical components from the heat and laser cutting outlets in the box before assembling so the LEDs are visible and power switch inlet could be added. Despite planning our design for a significant amount of time, I realized that there are always going to be on the spot changes when completing a design. Because of this, my team and I had to discuss each possibility and would only move forward when we all agreed on the best option.

escent light bulbs to retain heat and lined the inside of the box with aluminum to retain heat for a longer duration of time through insulation and radiation. As we continued to work, there were many decisions and adjustments that needed to be made such as adding a closed off housing area to separate the electrical components from the heat and laser cutting outlets in the box before assembling so the LEDs are visible and power switch inlet could be added. Despite planning our design for a significant amount of time, I realized that there are always going to be on the spot changes when completing a design. Because of this, my team and I had to discuss each possibility and would only move forward when we all agreed on the best option.

After completing the heating compartments, we then started on the base of the design to m ake the device mobile. Because we had already assembled the heating compartment with limited available space, figuring out a way build a secure and stable attachment point between the legs of the cart to the heating compartment was a challenge. At first, we attempted to attach for legs as a base and then add the wheels however, when we test it, legs were uneven causing it to be slanted (sawing perfectly level and straight lines with a hand saw is difficult). Unfortunately, this meant we had to either redo the base with the hopes of it being level or try an alternate method of attaching the wheels. Knowing that we were still unable to cut straight, we came up with another design that relied less on how the pieces of wood were cut but still stable enough to handle any obstacles when being pushed and this time we were happy with the physical results.

ake the device mobile. Because we had already assembled the heating compartment with limited available space, figuring out a way build a secure and stable attachment point between the legs of the cart to the heating compartment was a challenge. At first, we attempted to attach for legs as a base and then add the wheels however, when we test it, legs were uneven causing it to be slanted (sawing perfectly level and straight lines with a hand saw is difficult). Unfortunately, this meant we had to either redo the base with the hopes of it being level or try an alternate method of attaching the wheels. Knowing that we were still unable to cut straight, we came up with another design that relied less on how the pieces of wood were cut but still stable enough to handle any obstacles when being pushed and this time we were happy with the physical results.

Despite having completed majority of our design, there are only a couple of days left before final presentations and we still have a lot to do, but I am hopeful that we can get it done in time. As for our time outside of the design studio, we had the opportunity to have dinner with the past Malawian interns who did their internship in the United States last year. It was really nice to compare our experiences having both traveled to different countries to work on global health projects. Something I found interesting was that they actually did their internship while Rice was still in school, so they worked mainly with Rice 360 fellows rather than other undergraduate students. I personally was curious to hear some of the cultural differences they found shocking in the US. Apparently one observation they had is how people treat pets as members of their family especially dogs. I can understand their surprise considering all the dogs I have yet to see in Malawi are either guard dogs or strays. It turned out to be a very nice dinner and I wish we could have spent more time with them or even met while we were at Rice.

On another note, here are some pictures from the adventures we have had over the past couple of weeks that I hope you enjoy as much as I did.

Until next time!

-S