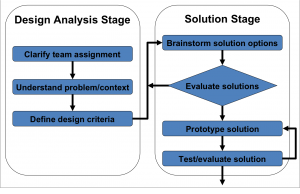

This past week, two of my professors from Rice (Dr. Saterbak and Dr. Wettergreen) came to Blantyre to teach a weeklong Engineering Design workshop for the faculty at the Polytechnic. In this workshop, they focused in on the seven step engineering design process, which includes:

1) Clarify team assignment

2) Understand problem and context

3) Define design criteria

4) Develop solution options

5) Evaluate solutions

6) Prototype solution (iterative)

7) Test solution (iterative)

In addition to this design process, they also spent time on scoping problems, low-fidelity prototyping and how to incorporate design into existing coursework. I had a lot of fun helping them out with all of the stages of the workshop, but by far my two favorite components were the low fidelity prototyping day Dr. Wettergreen led, and the scoping missions into the community.

The low fidelity prototyping session was very informative and also very fun! Dr. Wettergreen laid out all of the prototyping supplies (most of which were acquired in Blantyre and which could be as simple as a handful of toothpicks or a stack of newspapers) around the room in an inviting, slightly messy fashion to encourage the faculty to really explore all of the available materials. Interspersed on the tables were several games, activities and challenges that promoted creative thinking, hand eye coordination, rapid prototyping and kinesthetic learning. It was really fun to watch the progression of the faculty: at first they were all quite hesitant, but by the end everyone was loud, involved and making quite the mess! For Sarah, Emily and me the session was especially helpful because we plan to execute something like it for the new biomedical engineering student orientation we are helping to plan.

For the scoping missions, Dr. Saterbak led a team to the orthopedic department at QECH, Dr. Wettergreen led a team to the Carlsberg brewing factory, another team went to an energy company, and I tagged along with a team that went to Lafarge cement grinding plant. From what I saw on my visit and what I heard from Dr. Saterbak, Dr. Wettergreen and some of the Poly faculty, all of the scoping locations were very receptive to a burgeoning collaboration between the Poly students in design courses and the community. They were enthusiastic about Poly students pursuing projects that could help their respective businesses and continued visits from Poly faculty/students and communication between the respective institutions. It was really cool for me to witness such excitement and positive energy at the very beginning stages of what looks to be a very long term and fruitful set of relationships for all parties concerned.